Two years after the pandemic’s initial impacts, construction supply prices and availability have not returned to pre-Covid levels. This remains one of the sector’s biggest difficulties. Find out what you can do to safeguard earnings and maintain project schedules.

1. Control costs and availability by using more precise takeoffs

Even when prices are low and supply is steady, it’s never smart to waste building materials. It may be especially harmful to the bottom line in an atmosphere of high prices and overall scarcity, and can easily put a wrench in carefully planned project timelines. On-screen digital takeoff capabilities, a key component of the ConstructEM estimating platform, are perfect for speed and accuracy. Human measurement and computation errors will be eliminated, reducing overages.

2. Protect Profits with Periodically Update Costing Databases

Building and maintaining a constantly updated database for construction estimates is not a realistic requirement for many firms. Use a digital estimating platform with quarterly updates and regional KPIs. One of the three database choices offered by the ConstructEM estimating tool is RS Means data, and it works well. Its quarterly updated building costs data enables pre-construction managers, architects, engineers, and contractors to forecast, monitor, and control costs with remarkable precision.

3. Fasten Delivery by Placing Material Orders Specific to The Project

Any enjoy ordering bulk shipments, assuming they’re available, is usually offset by the time and labor needed to store and manage the materials. Overordering construction Ingredients might place you at the back of the line when supplies are low. Daily material orders are also difficult because delivery isn’t guaranteed and shipping and handling costs raise prices.

4. Formulate Conceptual Estimates in a Reliable Project Baseline

Materials that are hard to get by might significantly affect project deadlines and predicted construction costs. It’s important to predict expenses and adapt timelines based on comparable past initiatives. Contextual estimating tools, which utilize past data to better plan and understand future projects, are typically incorporated in construction software. ConstructEM conceptual estimating helps contractors forecast costs and delays by combining source unit pricing with new project inputs. They can also more readily make changes to material choice and design.

5. Lower the Risk of Punishments by Extending Timelines

First, understand the effects of materials shortages, which include higher prices and longer construction timelines. A crucial baseline for construction project completion is provided by historical data gathered on digital estimating tools like ConstructEM. This data is a trustworthy model that can be adjusted to reflect the most recent material availability. Completion addendums that address shortages may reduce legal challenges and fines for delayed projects.

6. Include A Cost Escalation Clause That Is Airtight

As building material costs vary, uncapped escalation clauses are becoming increasingly popular in construction contracts. The escalation clause adjusts fees, wages, and operational expenditures based on market values. It transfers responsibility for rising costs, such as labor or material shortages, from the general contractor (GC) to the project owner, providing crucial protection when material prices might increase suddenly.

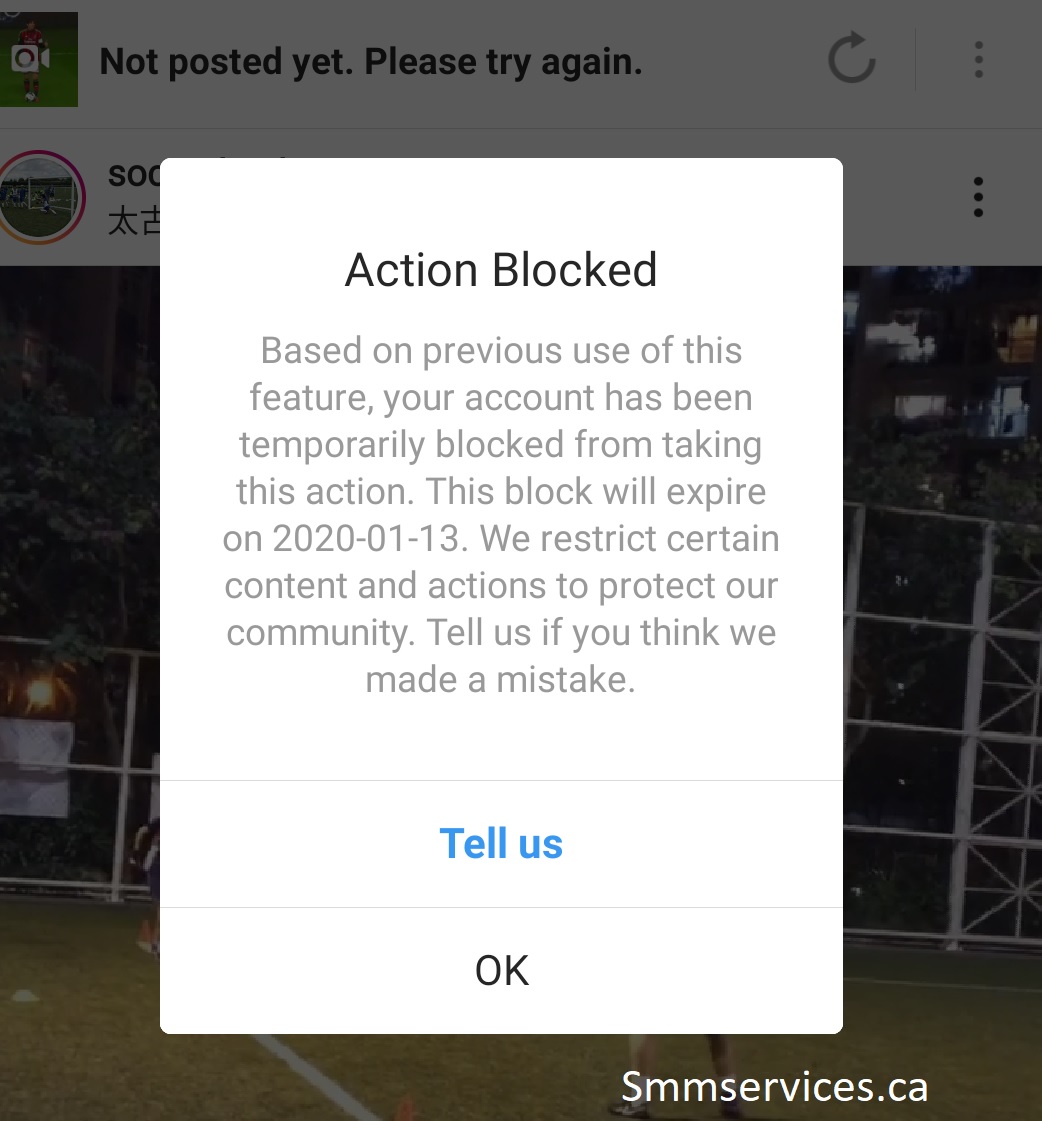

7. Better Communicate with Clients, Suppliers, And Subcontractors

Industry experts concur that open communication with stakeholders throughout the early design phases of a construction project, especially with project owners, is the best way to handle difficulties linked to material supply. If and when price increases and/or shortages occur, contractors who use an efficient Customer Relationship Management (CRM) strategy—supported by industry-specific CRM applications—are better able to establish and maintain strong relationships with engineers, architects, owners, and other project decision-makers; as a result, the likelihood of a mutually beneficial solution is significantly increased.

8. Change Your Sourcing Plan And Create Back-up Options

Being a devoted client to your suppliers makes commercial sense at the best of times—when construction supplies are affordable and costs are more or less consistent. In the building industry of the post-pandemic age, the rules are different: companies with varied supply chains are less impacted when resources are scarce since diversity greatly enhances the possibility of acquiring materials from other sources. Creditworthiness, a history of on-time payments, and other good business practices may contribute to the “preferred” status contractors require when vying for rare supplies. As competition for available resources increases, suppliers naturally become more selective about who they support.

Also Read: How to start construction business?